What is LED and what is an LED Chip?

LED chips or LED - A semiconductor device called a light-emitting diode (LED) emits light when current flows through it. Light is created when electrical current-carrying electrons and holes come together inside semiconductors. LEDs are tiny lamp beads that are simple to integrate into a circuit. However, it does not burn filaments, uses less electricity, and produces less heat than incandescent lamps. They have a lifespan equal to conventional transistors and illuminate by the movement of electrons in semiconductor materials.

Compared to incandescent lights, the service life of LEDs is thousands of hours longer. LEDs are one of the most widely used technologies for lamp lighting because of these benefits. The three main categories are DIP LED, SMD LED, and COB LED.

LED Chips

Different LED chips are used for automotive lightings such as Chip-on-board (COB), Chip Scale Package, and many others. Let’s discuss them one by one.

Chip-on-Board (COB) LEDs Chips

In LED lighting, Chip-on-Board (COB) is a relative innovation. It employs several diodes, typically 9 or more, that are packaged as a single lighting module and directly bonded to the substrate. This layout uses less room and has the most lighting possibilities.

Along with powerful LED floodlights and spotlights, COB LEDs are also used in compact devices like cameras and smartphones. They provide multi-directional or uniform light in all directions with a more compact design. Instead of appearing as individual lights when lit, the structure resembles a lighting panel.

A COB chip produces far more lumens per square inch than a standard LED since it has many more light sources in the same amount of space. The actual light output can range from a few hundred to thousands of lumens per COB LED wafer, depending on the design and power. The advantages of COB LEDs include enhanced thermal resistance, a bigger cooling surface, better illumination quality, and increased light output. Less heat is generated by its fewer components and more effective packaging, which also improves heat transfer to heat sinks.

Additionally, the COB architecture is less likely to malfunction in hot conditions (as compared to SMD LEDs).

Use of COB

High-bay lighting commonly uses COB LED lights to replace outdated metal halide lamps with solid-state alternatives. They are employed in loading docks, manufacturing facilities, distribution centers, and other industrial settings. High-output track lights and downlights frequently contain COB lights. They are also utilized for outdoor facilities that require a broad distribution of light over a big area, like parking lots, streets, and outside buildings.

Chip Scale Package (CSP) - LED Chips

"Chip Scale Package" is referred to as CSP. CSP technology, unlike SMD, enables the chip to be applied directly to the PCB board. This technique avoids two potential LED failure sites by doing away with the requirement for a holder and alloy wire. Additionally, CSP chips are smaller than SMD chips but have a higher intensity and use less current. A prime illustration of how a tiny LED signal lamp can have so much light in a compact container is the DAMA MINI 194 with 9CSP (The number in front shows the number of CSP chips). As with anything tech-related, CSP offers advantages over SMD, hence we believe that it will eventually overtake SMD as the most widely used type of LED.

Important Points to Know About CSP LED Chips for LED Headlights

- CSP LEDs are equivalent to one LED chip or can be 20% more expensive.

- CSP LEDs produce a lot of light. This enables it to emit high-performance light despite its small size. Due to its wide light angle, it provides a more uniform illumination performance.

- Unlike standard SMD LEDs, CSP LEDs do not have wire connections. They become more stable products as a result. lessens its cost as well. Better thermal performance than standard LEDs.

- In the automotive sector, CSP LEDs are frequently employed, particularly for car lighting (LED Headlights).

CSP Chip Advantages

- A Minimal Size With Maximum Emitting

Maximum lumen production is ensured by using a top-emitting flip chip with a phosphor layer at the top that measures 1.0mm x 1.0mm x 0.2mm.

- Brightening Miniaturisation

The smallest and narrowest beam angles are made possible by CSP. A spotlight's relative reflector size can be cut in half in height and half in radius.

CSP Chip Features

There are many useful features of CSP chips in LED headlights. Here are some for you to know:

- Package At Real Chip Scale (1.0 Mm) Featuring A Top Emitter That Is Ideal For High-Density Clustering, Tunable CCT, And A Small Spot Light With A Tight Field Of View.

- Top Of Class Angle Over Color (COA)

- Offered With Cri 80 And 90

- Variety of CCT options

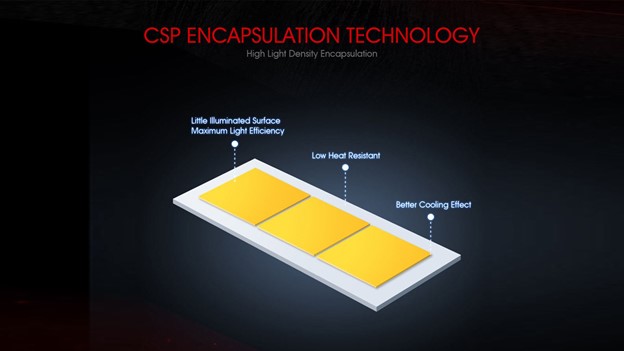

CSP Encapsulation Technology

In the automobile industry, CSP LEDs are frequently used in headlights and headlight bulbs (LED headlight bulbs). There is little room for LED installation for high light output for vehicle headlights. Additionally, the limited space makes cooling more difficult. CSP LEDs are capable of filling this need. Additionally, the LEDs on the car started to malfunction due to constant shaking. CSP LEDs, as opposed to SMD LEDs, do not have wire connections, hence they have a longer lifespan.

Why CSP Chips are better than others?

CSP chips have a smaller size with high lumination power. Lambertian emitters with the maximum brightness at the smallest size on the market are Chip Scale Package (CSP) LEDs. They are the ideal choice for dense clustering and high luminous flux output because of their exceptional quality without bond wires or the necessity for spacing.

Summarizing CSP Chips and its Advantages

- Improved thermal contact between the bottom epi layer and the heat sink through the metal-metal interface.

- Higher current densities result in increased device lumen output.

- High reliability with no wire bonding, a simplified attach procedure, and a smaller package

- Smaller footprint results in increased package density.

- Surface mount technology facilitates easy integration on boards.

- Flexible attachment with LED headlight housing

Final Words

At SKLED tech, we manufacture LED headlight bulbs with high-quality LED chips to provide with best lighting and lumens. Request a quote now to get the LED headlight bulbs for your car with highly functional LED chips with a longer lifespan.

Recent Blog

-

-

-

2022-12-23What is Plug and Play LED Lighting?

2022-12-23What is Plug and Play LED Lighting? -

-

-

2022-12-045 Easy Ways to Fixing Your Broken LED Lights

2022-12-045 Easy Ways to Fixing Your Broken LED Lights -

-

2022-11-30Does CAN Bus work with LED headlights?

2022-11-30Does CAN Bus work with LED headlights? -

2022-11-2910 LED Headlight Advantages You Need to Know

2022-11-2910 LED Headlight Advantages You Need to Know -

-

-

-

-

-

-

-

-

2023-10-26China 134TH Canton Fair 2023

-

2023-04-24Automec 2023: SK Lights Up São Paulo Expo

-